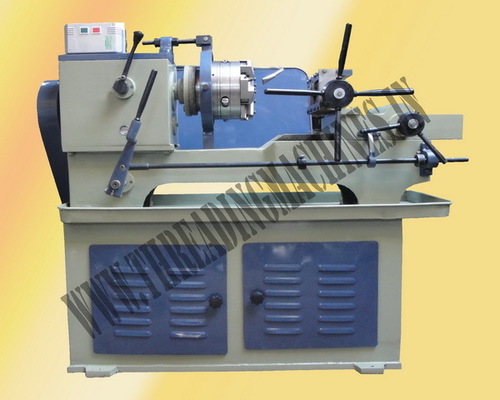

MS Bolt Threading Machine

MOQ : 1 Unit

MS Bolt Threading Machine Specification

- Lubricating System

- Automatic lubrication

- Control System

- Manual lever and electrical controls

- Features

- Robust frame, high torque, replaceable chasers

- Motor Power

- 3 HP

- Power Rating

- 2.2 kW

- Machine Type

- Bolt Threading

- Drive

- Belt & Pulley Drive

- Accuracy

- 0.1 mm

- Production Capacity

- 300 bolts/hour

- Noise Level

- <75 dB

- Voltage

- 415 V

- Cooling System

- Integrated coolant tank

- Frequency

- 50 Hz

- Product Type

- Bolt Threading Machine

- Power Source

- Electric

- Power

- 3 HP

- Pressure

- Hydraulic, adjustable

- Surface Treatment

- Painted

- Dimension (L*W*H)

- 1200 x 800 x 1100 mm

- Weight (kg)

- 450 kg

- Color

- Blue / Light Grey

- Usage & Applications

- Suitable for threading MS bolts, rods, and pipe fittings

- Threading Length

- up to 110 mm

- Max Bolt Diameter

- 6 mm to 36 mm

- Main Shaft Bearing Type

- Heavy Duty Ball Bearing

- Material Compatibility

- Mild Steel, Stainless Steel

- Spindle Speed Controls

- 5 Speed Levels

- Safety Features

- Overload Protection, Emergency Stop

- Input Phase

- Three Phase

- Clamping Mechanism

- Quick Lock Vise System

- Installation Area Required

- 1300 x 900 mm

- Packing Type

- Wooden Box

- Thread Standard Supported

- Metric/Imperial

MS Bolt Threading Machine Trade Information

- Minimum Order Quantity

- 1 Unit

- Payment Terms

- Cheque

- Supply Ability

- Unit

- Packaging Details

- As per Retirement

- Main Export Market(s)

- Australia, North America, Eastern Europe, Western Europe, Africa, Middle East, South America, Asia, Central America

- Main Domestic Market

- All India

About MS Bolt Threading Machine

We feel proud to introduce ourselves as the leading trader, exporter and supplier of Bolt Threading Machine that is used for cutting external thread on components by Chasing method. With the help of HSS Tangential Chasers, this machine can make Matric, BSP, BSPT, NPT, UNF, UNC, BSW, Acme Threads B.S.F., etc. This Bolt Threading Machine is widely demanded in the industry, owing to its features like simple operation, easy installation, sturdy construction and enhanced durability.

Range of RG Threading Machines and Die Heads.

- 1/4" to 1" do/-

- 3/8" to 1.1/2" do/-

- 1/2" to 2.1/2" do/-

- 1" to 4" Capacity do/-

(Bed Type)

MODEL | 1/4" to 1" | 3/8" to 1.1/2" | 1/2" to 2.1/2" | 1" to 4" |

SADDLE MOVEMENT | 10" | 10" - 12" | 16"/12" | 10" - 12" |

SPINDLE SPEED RANGE | 60-90 | 60-90 | 60-90-12 | 40-75-115 |

NUMBER OF SPINDLE SPEED | 2 | 2 | 3 | 3 |

THREADING CAPACITY | 1/4" to 1" | 3/8" to 1.1/2" | 1/2" to 2.1/2" | 1" to 4" |

PRODUCTION PER HOUR | 60-80 | 60-80 | 70-90 | 35-40 |

H.P. REQUIRED | 3 H.P. | 3 H.P. | 7.5 H.P. | 12.5 H.P. 960 |

LEAD SCREW | OPTIONAL | OPTIONAL | OPTIONAL | PROVIDED |

WEIGHT (KG) APPROX. | 500 | 550 | 990 | 1600 |

Superior Threading Performance

Delivering high torque and fine accuracyup to 0.1 mmthe MS Bolt Threading Machine excels at creating dependable threads on bolts, rods, and pipe fittings. Its integrated coolant tank and automatic lubrication ensure consistent results and extended machine lifespan, even during intense production cycles.

Efficient & Safe Operation

With features such as overload protection and an emergency stop button, safety is prioritized during every use. The quick lock vise mechanism guarantees rapid changeovers, while spindle speed controls promote adaptability to various material types and sizes. Manual and electrical controls enhance operator convenience.

FAQs of MS Bolt Threading Machine:

Q: How do I operate the MS Bolt Threading Machine for optimal results?

A: To operate, securely clamp your bolt in the quick lock vise, select the desired spindle speed from the five available levels, and use the manual lever and electrical controls to start threading. Ensure the integrated coolant tank is filled and the automatic lubrication system is active for smooth operation.Q: What materials can I thread using this machine, and what thread standards are supported?

A: The MS Bolt Threading Machine is suitable for threading mild steel and stainless steel bolts, rods, and pipe fittings. It supports both metric and imperial thread standards, accommodating a wide range of application requirements.Q: When should I use the overload protection and emergency stop features?

A: The overload protection is automatically triggered if the machine is under excessive stress, preventing damage. Use the emergency stop button to immediately halt operations if you encounter any hazardous situation or equipment malfunction.Q: Where can this threading machine be installed, and what space is required?

A: Install the machine in an area at least 1300 x 900 mm to accommodate its footprint and allow space for operation and maintenance. It is suitable for factory floors, workshops, and industrial settings where three-phase power is available.Q: What is the threading process and production capacity of the machine?

A: The operator clamps bolts into the quick lock vise, selects the desired speed, and initiates threading. The machine threads with high precision (0.1 mm) and can process up to 300 bolts per hour, making it highly efficient for high-volume manufacturing.Q: What are the main benefits of using this threading machine?

A: Users benefit from its robust construction, precision threading, adjustable hydraulic pressure, integrated cooling and lubrication, and high safety standards, all contributing to reliable, efficient, and long-lasting performance.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Bolt Threading Machine Category

Industrial Bolt Threading Machine

Minimum Order Quantity : 1 Unit

Cooling System : Integrated coolant system

Machine Type : Bolt Threading Machine

Pressure : Hydraulic (adjustable as required for threading operation)

Power Rating : 3 kW

Frequency : 50 Hz

We are interested in receiving only Export inquiries.

Our Export Percentage is 100 %.

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS