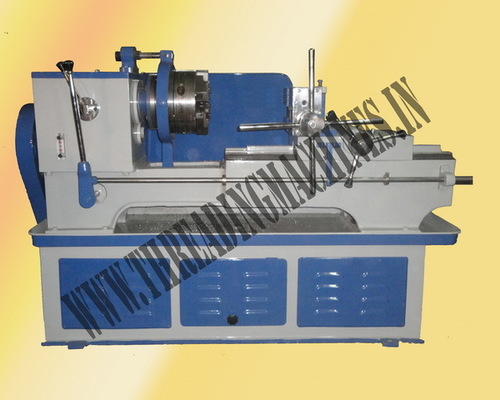

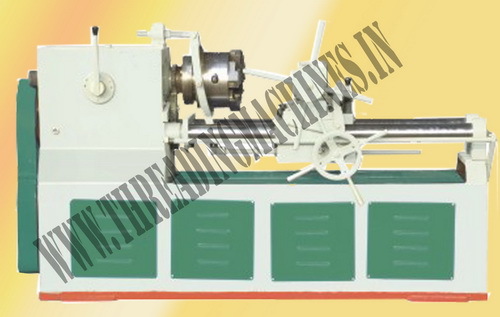

MS Pipe Threading Machine

MS Pipe Threading Machine Specification

- Weight

- Approx 280 kg

- Condition

- NEW

- Motor Speed

- 1440 RPM

- Capacity

- 1/2 to 4 (Pipe Diameter)

- Power

- 2 HP

- Machine Type

- Pipe Threading

- Phase

- Single Phase

- Usage

- Industrial Pipe Threading

- Color

- Blue & Metallic

- Raw Material

- Mild Steel (MS)

- Place of Origin

- India

- Output

- Threaded Pipes

- Dimension (L*W*H)

- 1300 mm x 600 mm x 800 mm

- Product Type

- MS Pipe Threading Machine

- Transportability

- Wheels Provided for Mobility

- Maximum Pipe Length

- Up to 6 meters

- Threading Die Head Type

- Manual Adjustable

- Applications

- Plumbing, Construction, Fabrication Workshops

- Tool Included

- Threading Dies, Reamers

- Surface Finish

- Powder Coated

- Noise Level

- Less Than 75 dB

- Cutting Oil System

- Integrated with Oil Pump

- Body Material

- Heavy Duty Cast Iron

- Thread Type

- BSPT or NPT

MS Pipe Threading Machine Trade Information

- Payment Terms

- Telegraphic Transfer (T/T)

- Supply Ability

- Unit

- Delivery Time

- Days

- Packaging Details

- As per Requirement

- Main Export Market(s)

- Australia, North America, Eastern Europe, Western Europe, Africa, Central America, Middle East, South America, Asia

- Main Domestic Market

- All India

About MS Pipe Threading Machine

We offer a wide assortment of Pipe Threading Machines to our esteemed clients. These are extensively used in threading process on steel pipes, PVC pipes, steel bars, bolts, scaffolding screw jacks, nipples, etc. They are also acknowledged for their greater longevity and smooth operation.

Model | 1/4" TO 1" | 3/8" to 1.1/2" | 1/2" TO 2. 1/2" | 4"TO 8" |

Saddle Movement | 10" | 10" - 12" | 12" _ 16" | 10" _ 12" |

Spindle Speed Range | 60-90 | 60-90 | 60-90-120 | 25 - 50 |

Number of Spindle Speed | 2 | 2 | 3 | 2 |

Threading Capacity | 1/4" TO 1" | 3/8" to 1.1/2" | 1/2"TO 2. 1/2" | 4" TO 8" |

Production per Hour | 60-80 | 60-80 | 70-90 | 15-20 |

H.P. Required | 3 H.P. | 3 H.P. | 7.5 H.P. | 20 H.P. 960 |

Lead Screw | OPTIONAL | OPTIONAL | OPTIONAL | PROVIDED |

Weight (KG) Approx. | 500 | 550 | 990 | 2500 |

Precision Threading for Industrial Needs

Engineered for accuracy and reliability, this pipe threading machine supports both BSPT and NPT thread types, making it suitable for various industry standards. The manually adjustable die head allows for flexibility in threading operations, accommodating pipes up to 6 meters in length. Its powder-coated surface finish and sturdy construction guarantee long-term performance in demanding environments.

Integrated Features for Enhanced Operation

The system includes an integrated oil pump for continuous lubrication during threading, which prolongs tool life and improves thread quality. Essential tools such as threading dies and reamers are included, ensuring the machine is ready for immediate use. Transportability is simplified with built-in wheels, allowing easy relocation across job sites or workshop spaces.

FAQs of MS Pipe Threading Machine:

Q: How does the integrated oil pump system enhance the threading process?

A: The integrated oil pump provides continuous cutting oil directly to the threading area, significantly reducing friction and heat. This results in smoother threads, longer tool lifespan, and improved overall efficiency during prolonged threading operations.Q: What types of threads can this machine produce, and how are they selected?

A: This machine is capable of producing both BSPT and NPT threads. Selection is made by adjusting the manual die head and using the appropriate threading dies included with the machine to match the required thread type for your application.Q: When is this pipe threading machine best utilized?

A: The machine is ideal for industrial use where precision, efficiency, and durability are crucialparticularly in plumbing, construction sites, and fabrication workshops. Its capacity to handle pipe diameters from 1/2 to 4 inches and pipe lengths up to 6 meters accommodates a broad range of threading needs.Q: Where can the machine be easily transported or set up?

A: Thanks to its heavy-duty wheels, the machine can be conveniently moved between job sites, workshop areas, or storage locations, supporting flexibility in diverse work environments.Q: What is the process for adjusting the die head for various pipe diameters?

A: The die head of the threading machine is manually adjustable. Simply select the appropriate threading die for the desired diameter and use the adjustment mechanism to secure it. Follow standard safety protocols during setup to ensure precise and secure threading with each use.Q: What benefits does the machines body material provide?

A: Constructed from heavy-duty cast iron, the machine offers excellent stability, vibration resistance, and longevity. The robust frame ensures the machine can endure continuous industrial use with minimal maintenance.Q: How do the included tools support pipe threading tasks?

A: The machine comes equipped with threading dies and reamers, providing operators with everything needed to start threading jobs right away. These tools are specifically tailored for use with the machine, ensuring consistent thread quality and operational efficiency.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Pipe Threading Machines Category

Heavy Duty Pipe Threading Machine

Price 00 INR / Unit

Minimum Order Quantity : 1 Unit

Dimension (L*W*H) : Approx. 500 x 350 x 450 mm

Output : Threaded Pipes

Product Type : Heavy Duty Pipe Threading Machine

Raw Material : Mild Steel/Alloy Steel

Scaffolding Pipe Threading Machine

Minimum Order Quantity : 1 Unit

Dimension (L*W*H) : 1200 mm x 650 mm x 800 mm

Output : Pipe Threading

Product Type : Scaffolding Pipe Threading Machine

Raw Material : Mild Steel

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS